Customer Story

Who are Smyczek?

Founded in 1985 in Verl, Smyczek GmbH is one of the leading specialists for PCB assembly in Germany. Since the end of 2009, Smyczek has been part of the Beckhoff Group of Companies and acts as the main supplier for Beckhoff control technology flat modules. With about 790 employees, Smyczek also performs test field services and manufactures automation modules on a production area of 22,000 m². The company is headed by Managing Director Michael Schlegel.

A Wealth of Experience

Specialized in the assembly of printed circuit boards since 1985.

Large Capacity

About 790 employees work on a production area of 22,000 m².

Further Information

Here you can find out more about Smyczek and the Beckhoff Group.

The Challenge

Smyczek GmbH produces and assembles electronic assemblies and complete device units. The range of services includes PCB assembly from prototype to series production. With modern machinery, different types of PCBs can be assembled efficiently.

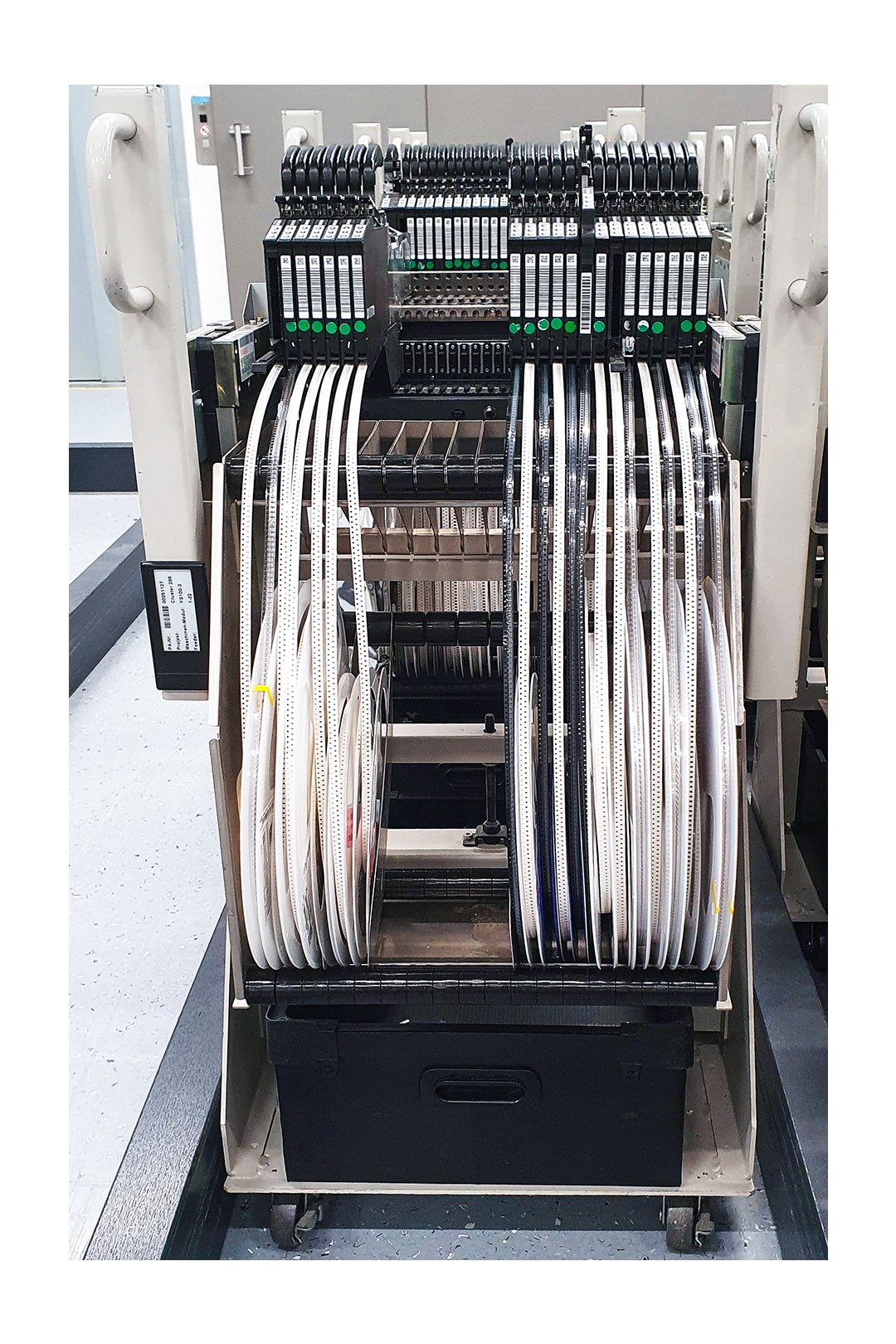

When surface-mounting electronic components onto printed circuit boards, so-called SMT assembly (Surface Mounted Technology), there used to be magnetic labels identifying each order on the SMT setup trolley. For this purpose, each label was marked with the job data and then fed with the respective job-specific components to the material infeed of the SMT assembly machine. Magnetic labels were then destroyed upon job completion.

The Solution

Since the middle of 2020, Smyczek has been using Faubel Logistics Labels instead of magnetic labels in its production process. The e-paper display integrated with the Logistics Label is written on at an upstream station with the help of an RFID reader. It displays the necessary job data fully and legibly. The Faubel Logistics Label is updated with each new job, and digital identification is, again, ready for use.

Because it is battery-free, the Logistics Label does not require any maintenance. In addition, the digitized process simplifies job documentation and can be tracked with one click. Currently, 820 labels are in use.

The Service

To ensure the successful integration of the Logistics Label into Smyczek's high-tech production, Andreas Bartling, Business Development Manager at Faubel, inspected the on-site conditions. Faubel's RFID Competence Center created a unique template based on these findings and the customer's requirements. In Verl, users were trained to use the software and hardware and given user manuals. Since integrating the Faubel-Logistics Label, Smyczek has reached technical support via a dedicated email address - even outside Faubel business hours.

![[Translate to Englisch:] Faubel-Mitarbeiter](/fileadmin/_processed_/9/7/csm_Felix_Fuchs_b6d5afc748.jpg)